If you’ve ever stood in a test kitchen staring at a row of sample trays wondering which batch should “win,” you already understand food product development: it’s equal parts inspiration and exhaustion.

One tweak too far, and the flavor is off. One ingredient swap to get pricing back in line, and suddenly shelf life becomes the problem. Multiply those decisions across suppliers, regions, distributor requirements, labeling rules, and production equipment differences, and food product development quickly turns into a high-stakes puzzle.

That’s where food product optimization with AI starts to make a real difference. Not by taking over creativity, but by helping food teams stop fighting blindfolded.

AI doesn’t cook. It doesn’t taste. But it does untangle massive amounts of data — past formulations, ingredient behavior, consumer trends, production results — so people can make sharper choices the first time, not after six rounds of trial and error.

Why Food Products Need Smarter Optimization

Changing customer expectations

Guest expectations don’t move slowly anymore. They swing.

Today someone wants indulgent comfort food. Tomorrow they want lighter portions or fewer additives. The week after that it’s a regional flavor trend that suddenly “goes viral” and everyone has to chase it.

Product teams are expected to respond immediately — without sacrificing consistency or safety. That’s a tall order when trends shift faster than development timelines. AI helps teams spot those shifts early by looking at real purchasing data and customer response patterns rather than relying only on gut feelings or trade-show buzz.

Rising pressure on quality and cost

Food manufacturers have zero breathing room:

- Quality needs to stay pristine.

- Costs refuse to cooperate.

- Ingredient pricing moves like a caffeinated squirrel.

Reformulations often don’t start with creativity — they start with economics. Cutting a fraction of cost out of a recipe usually triggers a chain reaction that challenges taste and performance. AI helps teams evaluate these tradeoffs before changes hit production so margins improve without sacrificing finished product standards.

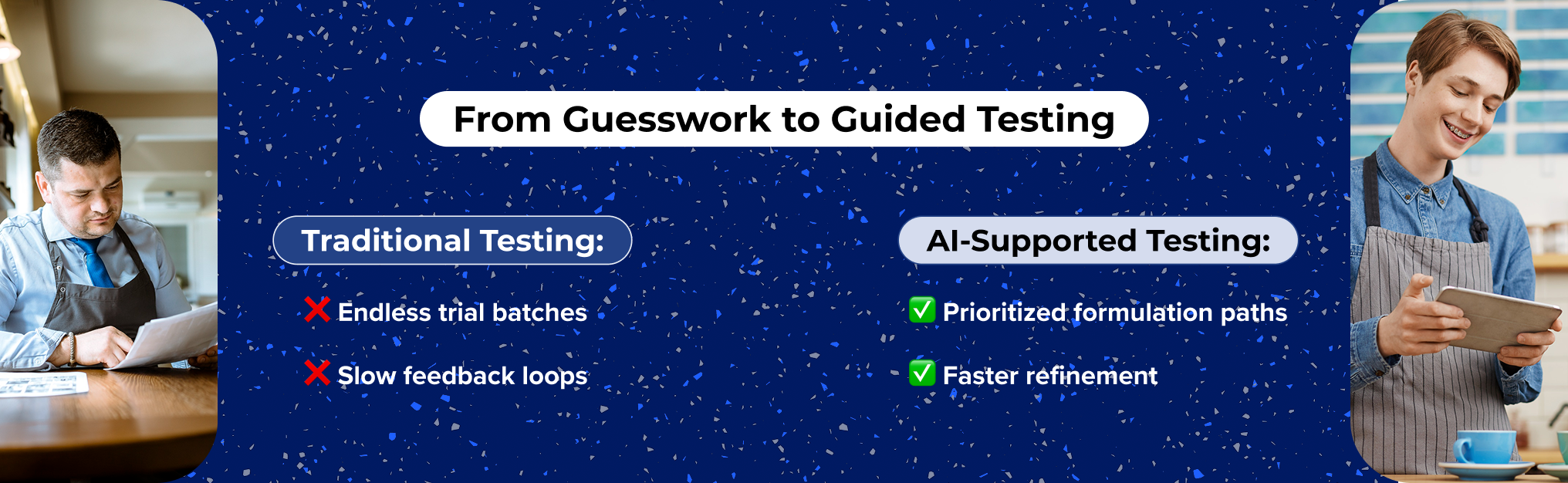

Limits of traditional product development

The old approach still dominates many operations: mix, bake, tweak, retry… repeat until something works.

It’s reliable, but painfully slow. Each loop burns time, ingredients, labor hours, and production slots. And usually, half the tests never had much chance of succeeding in the first place.

AI improves this reality by narrowing the field early. Teams don’t start with a dozen wild swings anymore. They start with fewer, smarter options that already reflect how similar products have performed historically.

How AI Supports the Product Development Process

Help teams test product ideas faster

Instead of only testing with physical batches, teams can preview formulation changes digitally by comparing how similar ingredient combinations behaved in the past.

This doesn’t replace hands-on tasting — it prevents wasted tastings. Teams walk into testing sessions with better starting points, reducing the number of dead-end batches that were never going to make the cut anyway.

Make sense of customer feedback and trends

Feedback comes from everywhere: distributor reports, menu velocity data, social chatter, loyalty insights, operator complaints, chef panel notes.

Humans can’t process that at scale. AI can. It pulls all that noisy information together into usable patterns that reveal what’s actually happening with product demand, not what feels loudest in the moment.

Reduce manual trial and error

Ever chase a formulation idea for weeks just to realize it was doomed from the start?

AI shortens that loop. It flags combinations that historically led to texture breakdowns or shelf instability and points teams toward alterations that have worked elsewhere. Developers still test physically, but they stop chasing long shots.

Less wandering. More directed experimentation.

Where AI Brings the Most Value in Food Product Optimization

Enhance flavor and texture

Flavor tweaking isn’t guesswork anymore. AI shows how ingredient switches affected mouthfeel and taste balance across thousands of formulations, so teams start closer to the target instead of finding it by accident.

Improve shelf life

Shelf stability doesn’t always fail because of preservatives. Sometimes it’s moisture migration. Sometimes packaging interaction. Occasionally, temperature sensitivity during transit.

AI connects these dots using historical shelf-life data so teams can strengthen formulations before distribution problems ever show up.

Stabilize product quality

Minor ingredient variances add up. One supplier shift or processing change can subtly degrade consistency over time.

AI helps monitor where that drift begins so teams adjust before quality concerns turn into escalations or recalls.

Refine ingredient combinations

When substitutions become necessary, AI identifies ingredients that function similarly under real-world conditions — not just on paper — helping teams maintain integrity while keeping sourcing flexible.

How AI Helps Control Costs and Reduce Waste

Avoid unnecessary ingredient use

Many formulations pad ingredient levels higher than required as safety insurance.

AI helps calculate where excess use doesn’t contribute to flavor or stability, allowing formulas to be tightened without compromising performance.

Reduce failed product batches

Failed runs are brutal — labor loss, ingredient waste, disposal costs.

AI flags higher-risk formulation decisions in advance, minimizing batch failures before they become expensive learning exercises.

Plan smarter production volumes

Demand forecasting tools combine history, seasonality, and trend swings to support more accurate production targets. That reduces spoilage and prevents excess inventory discounting.

How Brands Can Begin Optimizing Products with AI

Understand what needs improvement

Adoption starts by identifying friction: development bottlenecks, waste issues, recurring quality inconsistencies.

AI works best when aimed at real problems rather than installed for novelty.

Choose practical AI tools

Food-specific platforms that focus on formulation support, quality modeling, and demand planning integrate more naturally than general data platforms built for other industries.

Test changes before scaling

Smart brands pilot first — validating insights in limited runs before rolling changes into full production.

Review performance regularly

AI tools need continuous input to stay accurate. Regular data updates and performance reviews keep models aligned with market changes.

How AI is Changing the Future of Food Products

More personalized food options

Smaller, faster product variations become possible without burdening development teams.

Faster product innovation

AI cuts testing cycles and speeds time-to-market while keeping risks manageable.

Smarter product decisions

Teams stop guessing. Creativity stays — uncertainty shrinks.

Why This Matters for Today’s Food Teams

Food product optimization with AI isn’t about handing recipes over to computers. It’s about giving food professionals better visibility and confidence inside a development process that’s gotten more complicated and more expensive than ever.

The kitchen doesn’t lose its soul, it gains a smarter compass.

Frequently Asked Questions

How does AI improve food products?

By analyzing historical formulations, market feedback, and production outcomes so teams can make smarter adjustments sooner and waste less time and product.

Is this useful for small food brands?

Absolutely. Smaller teams benefit from faster development cycles and fewer failed tests without expanding headcount.

Does AI replace food technologists?

No. AI supports the work technologists already do by improving planning and insight — creativity and compliance remain human-driven.

Click here to see how Dining Alliance supports smarter product development and purchasing decisions for your operation.