AI is literally changing how food is made. AI is helping food manufacturers work smarter, faster, and more sustainably by helping them find ingredients and package finished goods. Independent restaurant owners may not run production lines, but the technology that shapes this world has a direct impact on what ends up in your kitchen.

AI is making every part of food production better, whether it’s by making the quality more consistent, making it safer, or cutting down on food waste. What happened? More stable prices, fresher ingredients, and fewer problems with the supply chain. Operators can make better buying decisions for the future if they know how AI is used in food manufacturing today.

How AI is Changing Food Manufacturing

In today’s food manufacturing plants, technology has gone from helpful to essential. Teams now rely on smart systems that “listen” to equipment, recognize early signs of wear, and help prevent breakdowns before they happen. The same tools can spot subtle changes in texture, color, or temperature that might signal a quality problem—long before it ever reaches the production line.

Take a look at what’s actually happening inside the plant. You’ll see cameras watching each item that rolls down the line, picking up tiny differences in color or texture that people might miss. Sometimes it’s just a shade off — but that’s enough to catch before it ships out.

Over by prep, someone’s probably checking ingredient data on a screen. It’s not just numbers — it shows what’s being used and what’s left, so the team doesn’t make more than they need. That small bit of insight can save a ton of waste.

Walk into storage and it’s cooler there — literally and figuratively. Smart sensors keep tabs on the temperature and humidity without anyone needing to hover.

And when it’s time to ship? The system already knows which routes are clear and where demand is picking up, so trucks head out before the phone even rings. Everything just flows smoother that way.

Key Applications of AI in Food Manufacturing

Artificial intelligence has worked its way into almost every part of food manufacturing — from keeping quality in check to helping create what’s next on the product line. It’s changing the way teams think, work, and problem-solve across the industry.

Quality Control and Safety

- Let’s be real — quality control can make or break a brand. These days, most plants have eyes everywhere. You’ve got cameras and sensors watching the line, spotting weird textures, odd colors, or anything that doesn’t look right. Someone still has to make the call, but the system helps flag things before they spiral into a bigger issue. Fewer recalls, fewer headaches. And for restaurants, it’s one less thing to worry about — what comes through the door is safe, steady, and exactly what they expect.

Process Optimization

- Walk into any modern plant and you’ll see data everywhere. It’s tracking how long things cook, how fast they’re packed, even where the line starts to slow down. When something’s off, the system tweaks it in real time — no waiting, no guessing. That kind of precision cuts down on waste and keeps production moving without the usual hiccups. The payoff shows up later for operators: products arrive on time, look the same every batch, and perform exactly how they should. Reliable, simple, no surprises.

Supply Chain Management

- Ask any manufacturer what keeps them up at night, and supply chain issues are usually near the top. With smarter tech in the mix, teams can finally see what’s coming before it hits. They can spot when ingredient levels are dipping or when a shipment might get delayed, and adjust before it becomes a problem. That kind of foresight keeps inventory moving and shelves stocked. For independent restaurants, it means fewer “sorry, we’re out” moments and a steadier, more reliable flow of products day to day.

Product Development

- Manufacturers aren’t guessing anymore when it comes to new products — they’ve got data doing some of the heavy lifting. By looking at what customers are buying and what they actually want to see on labels, teams can experiment with cleaner ingredients or healthier recipes before a single batch is made. AI tools can run those tests virtually, so by the time production starts, the formula’s already been fine-tuned. It saves time, cuts down on waste, and helps operators keep up with changing diner trends without missing a beat.

Automation and Robotics

- You’ll see more robots on the floor these days, but they’re not taking over — they’re taking on the tough stuff. Tasks like packaging, sorting, and labeling can be repetitive or risky, and automation helps lighten that load. It keeps workers safer, speeds things up, and makes sure every box that goes out looks and performs the same. For restaurant operators, that consistency is everything — it means the product they get today matches the one they ordered last week, no surprises.

Benefits of Using AI in Food Manufacturing

Increased Efficiency and Productivity

In food manufacturing, there’s always pressure to do more with less. AI isn’t magic, but it’s helping teams make that happen in a few key ways:

- Catching problems early. When a machine starts acting up, AI spots it before it shuts everything down. No panic, no surprise repairs.

- Speeding up decisions. Instead of waiting on a report, teams get live data right on the floor. They can make quick calls and keep things moving.

- Keeping production steady. Packaging, shipping, logistics — all those little steps that usually cause slowdowns — run smoother when automation’s dialed in.

At the end of the day, it means fewer delays, faster turnaround, and a more reliable flow of products out to restaurants.

Improved Quality and Safety

Every batch has to be right — no exceptions. These days, smart systems help catch the little things people might miss, like a color that’s off or a seal that didn’t stick. Everything’s tracked, too, so if there’s ever a question about where an ingredient came from, the answer’s right there. For restaurants, that means safer food and way fewer headaches.

Reduced Waste and Enhanced Sustainability

Everyone’s trying to cut waste these days, and AI’s just making it easier to keep track of what’s really happening in production.

- It keeps an eye on how much is being made, so teams don’t overproduce and toss perfectly good food.

- It helps cut down on packaging that used to pile up or get tossed after one use.

- And it watches energy use across machines, catching spots where power’s being wasted.

Add it all up, and you end up with less waste, lower bills, and a supply chain that feels a lot cleaner — something both manufacturers and restaurants can actually feel good about.

Faster Innovation

You know how new product ideas used to take forever? Not anymore. With AI in the mix, teams can play around with recipes and ingredients on a computer first, instead of wasting time and batches in the kitchen. It cuts the process way down. Suddenly, a concept that once took months is ready in days, which keeps menus fresh and diners interested.

Future of AI in Food Manufacturing

The future of AI in food manufacturing is all about precision, transparency, and adaptability. As the technology matures, manufacturers will continue using AI to strengthen traceability, automate compliance reporting, and respond instantly to changes in consumer demand.

Picture this for a second:

You can trace an ingredient right back to where it started — no digging, no waiting. Manufacturers can tweak recipes on the fly when supplies shift, and energy use gets tracked in real time so waste doesn’t pile up.

That’s not some distant future. It’s already starting to happen, even in smaller plants that used to rely on spreadsheets and guesswork. The tech is leveling the playing field, giving everyone access to the same kind of insight big companies have had for years.

For independent restaurants, that’s huge. It means steadier supply, fewer last-minute shortages, and partners who actually understand what’s happening behind the scenes. The line between manufacturer and operator is blurring, and honestly, that’s a good thing — it builds a more connected, transparent food world for everyone involved.

The Bottom Line

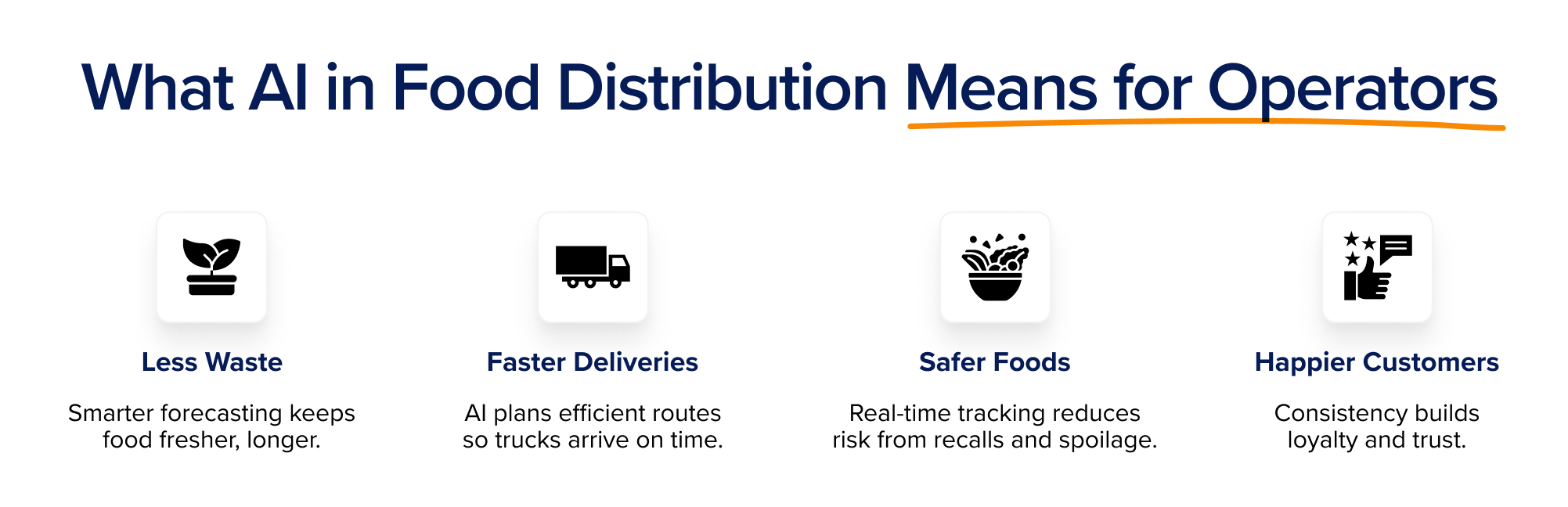

AI is quietly changing how food gets from the factory to the kitchen. It cuts down on waste, keeps safety standards tight, and helps every batch come out just the way it should. The end result? Better food, smoother operations, and less money slipping through the cracks.

At Dining Alliance, we’re tuned into what’s next. Our team connects operators with suppliers who share the same commitment to quality and innovation. When technology and foodservice move in the same direction, everyone wins — from the folks making the food to the people serving it.

See what smarter sourcing can do for your bottom line. Complete the form below and our team will connect you with the right supplier programs to save time, money, and stress.